- Apr 30, 2025

The Overlooked Partnership: ISO Standards and Lean Principles Working Together for Process Excellence

- Peter Papantonis

- General, Operations

- 0 comments

Introduction

In many organizations, Lean and ISO standards are viewed as separate initiatives — one focused on reducing waste and the other on maintaining quality compliance. But what if they weren’t just compatible — what if they were complementary? When used together, ISO standards and Lean principles can reinforce each other to drive sustainable improvement, improve outcomes, and create real organizational agility. Yet, in many industries, the full potential of this partnership remains untapped.

Understanding the Link

ISO standards — particularly ISO 9001 — are built around process-based thinking, continual improvement, and a focus on customer satisfaction. These are also core Lean principles.

Where ISO provides structure, consistency, and accountability, Lean offers flexibility, efficiency, and frontline engagement. When Lean tools are used to achieve ISO goals — or vice versa — the result is a system that doesn’t just check boxes but continuously evolves.

How Lean Principles Are Being Used Alongside ISO – Real Examples

Manufacturing: Driving Consistency with Flexibility

A mid-sized auto parts manufacturer uses ISO 9001 to ensure consistency in product quality and documentation. But it was Lean that helped them identify and eliminate bottlenecks in their assembly line. For instance, by applying 5S to workstations and value stream mapping, they improved both audit outcomes and customer satisfaction.

Healthcare: Raising the Bar for Safety and Efficiency

A hospital applying ISO 13485 standards for medical device management used Lean's visual management and standard work techniques to streamline their sterilization procedures. As a result, they reduced errors and improved inspection readiness — something ISO alone couldn’t achieve as efficiently.

Food & Beverage: When Only One System Is Used

A regional food processor maintained ISO 22000 certification for food safety but neglected Lean practices. Despite compliant documentation, they struggled with slow changeovers, overproduction, and frequent downtime. Without Lean, they missed opportunities to reduce waste and increase throughput. Compliance was high, but efficiency remained low.

Where Lean Is Missing — and What That Costs

-

Documentation Without Engagement

ISO systems can become paperwork-heavy if not supported by Lean’s focus on frontline involvement.

When processes are documented only for auditors — and not used by staff — improvement stalls.

-

Corrective Action That Fixes Symptoms, Not Causes

ISO requires corrective action for non-conformities, but without tools like the 5 Whys or A3 Thinking, organizations may only treat surface-level symptoms.

-

Lack of Standard Work = Inconsistent Execution

ISO may outline what must happen, but Lean shows how it should happen every time.

Without Lean’s focus on standardization and visual cues, even certified systems suffer from inconsistent results.

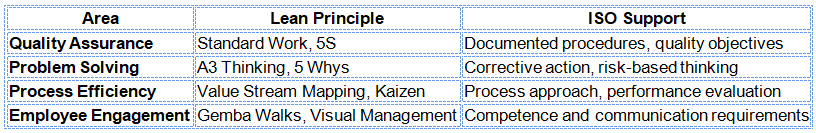

How to Better Integrate Lean and ISO

Why It Matters

Combining Lean and ISO is not about doing more work — it's about doing smarter work. ISO gives you the structure, and Lean brings the adaptability and innovation.

Companies that use both often see:

Lower internal failure rates

Higher employee engagement

Faster audit preparation

Reduced operating costs

Final Thoughts

Too often, ISO implementation becomes a top-down exercise, and Lean becomes a disconnected “project.” The real value comes when Lean principles are embedded into ISO systems, and vice versa.

Whether you're in healthcare, manufacturing, food production, or service delivery, the organizations that succeed long-term are those that build systems designed not only to comply — but to improve.